It’s always the same questions that arise during the planning and execution of laboratory experiments: Which chemicals are on hand in the laboratory and where can they be located?

This text was first published in the print an online edition of LABO.de April 2022 and translated to English; original article (LABO.de German), link for PDF download (German)

AUTHORS:

Jonas M Breitsameter and Moritz Kränzlein; PhD students in the group of Prof. Dr. Dr. h.c. Bernhard Rieger; WACKER-Lehrstuhl for Macromolecular Chemistry at the Technical University of Munich | Dr. Claudio Rolli; Founder and CEO FLUICS GmbH, Munich

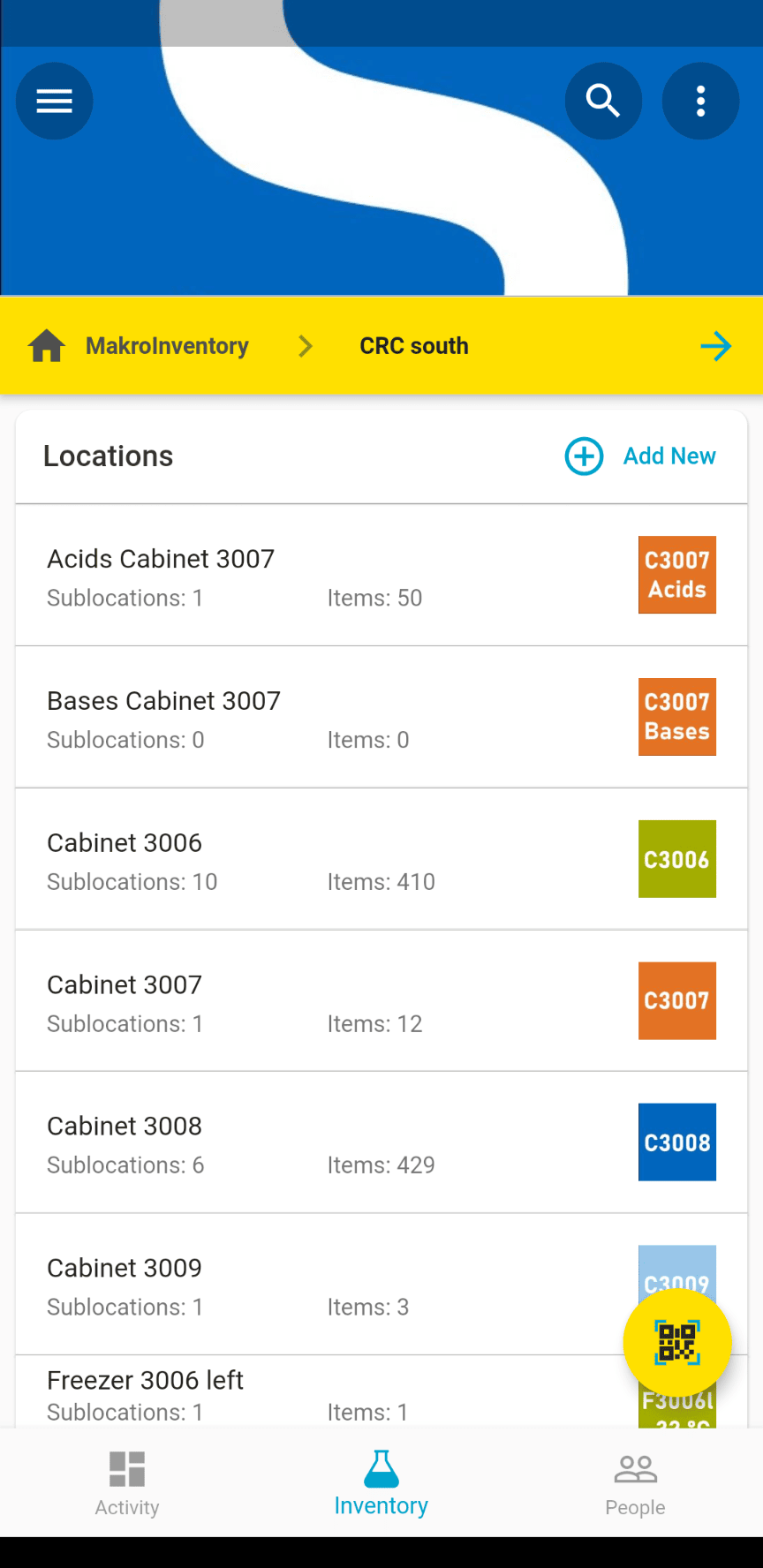

At the Chair for Macro-Molecular Chemistry of the Technical University in Munich you could recently find more than 2,500 chemicals, distributed among six safety cabinets, six shelves, four deep-freeze lockers, six refrigerators and four glove boxes. By “chemicals” we mean commercially available reagents, or substances created in the laboratory, which were stored according to different substance groups.

Finding a specific chemical can, therefore, take up a significant length of time. This can get especially bothersome when you don’t know what the packaging looks like (size of the flask, color of the lid, outer safety packaging, or bottled in a different container, etc.) “This is not just annoying and tedious, but it can, in reality, also lead to reordering or remaking a chemical several times because it could not be located in spite of searching for it for several hours”, said laboratory manager Dr. Carsten Troll from his own experience. And this, in spite of the fact that Excel tables had been created to manage chemical inventory. These tables were created for inventory management and for safety inspections where they served their purpose, but in practical daily laboratory work it took too much effort to keep them up-to-date in order to work with them efficiently or to locate chemicals.

How can we now bring order into the chaos of stored chemicals?

After an analysis of the current situation and discussions with the laboratory team (laboratory managers, researchers, lab technicians, and students), it became clear that only a database that is quickly accessible by all and continuously updatable would provide a practical solution. These conversations led to the following requirements that such a database must fulfill:

- The possibility for quickly and unambiguously updating the storage location, the volume used, and the opening date (in case of unstable compounds);

- A digitally searchable database that is accessible to all laboratory team members;

- Storage of a change history for better tracing of conducted experiments;

- Execution of a quick inventory check at regular intervals for inventory control;

- Reconciliation with reportable chemicals for safety inspections.

The decisive point: How is the connection of the digital database with the chemicals actually stored in the laboratory achieved?

Many times, the biggest challenge is the continuous maintenance of an inventory database: Storage location, filling level and opening date of tests and reagents, which freely move around the laboratory, must quickly and correctly be updated in the daily work at the laboratory. Manually updating a simple digital “database”, such as an Excel list, is normally work that is time-consuming, boring and especially prone to errors. What follows is usually a flood of partially updated Excel data rattling around laboratory computers.

Tagging with Identifiers for Scanning

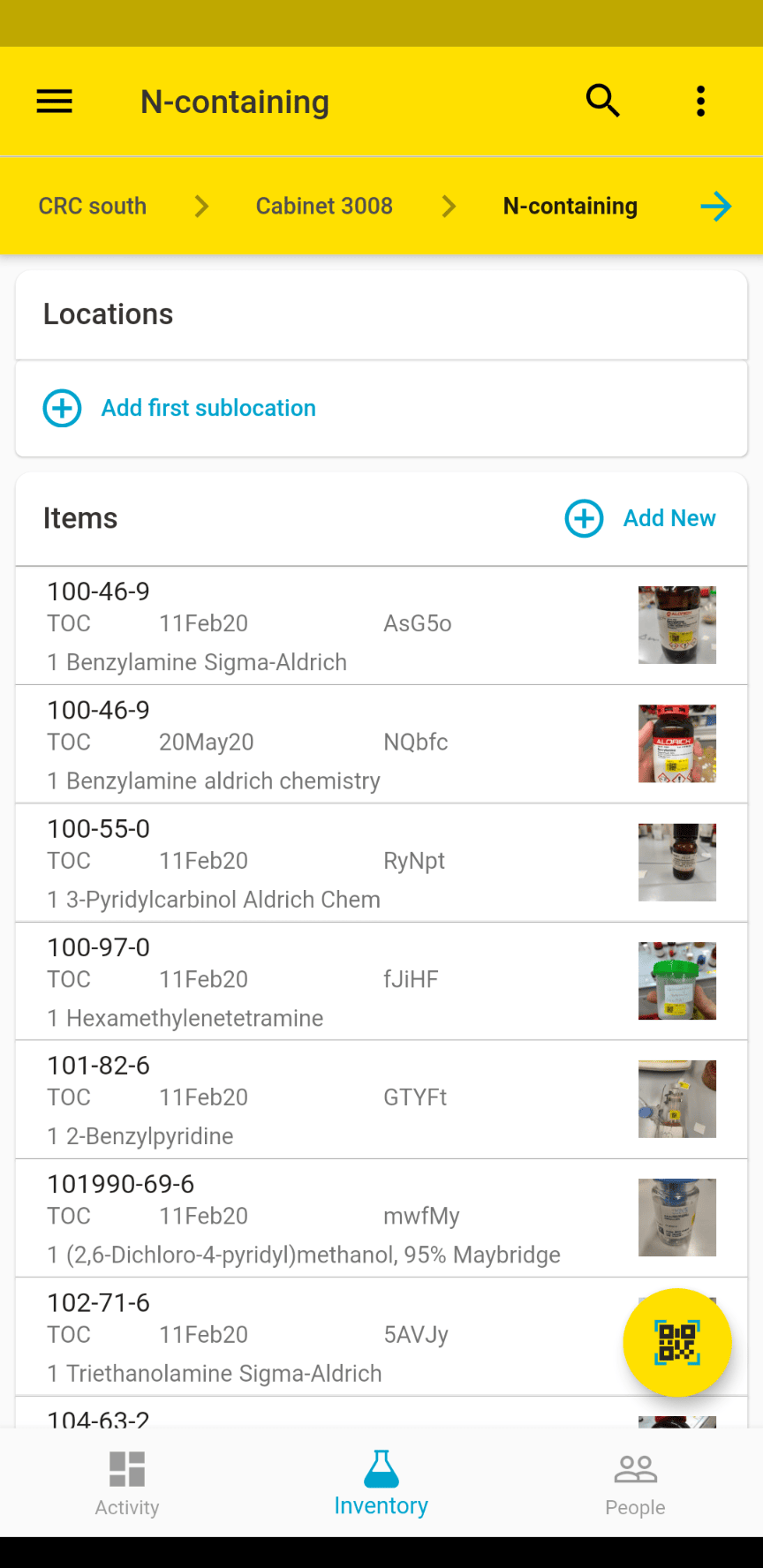

Labels with a unique QR code can be scanned either with a mobile app on a mobile device, such as a smart phone or a tablet, or they can be scanned with a barcode scanner connected to a computer. When such a label is sticking to a chemical, the information stored in the database can be accessed without errors and be updated as needed. If, in addition, the individual storage locations, such as lockers, shelves, drawers and boxes, etc., are labeled with a QR code, the storage locations stored in the database can also be updated within seconds.

After evaluating various inventory systems available in the market, Dr. Carsten Troll and doctoral candidates Jonas Breitsameter and Moritz Kränzlein, who are also responsible for the implementation, decided on the “FLUICS CONNECT” solution. It allows the access and editing of an online workspace (the database) from a computer with a browser or from a smart phone or tablet with a mobile app. This database is accessible to the entire laboratory team. Labels with QR codes for chemicals and storage locations can be printed, as needed, by one or several web-enabled label printers. The ability to upload photos via smart phone has turned out to be a special highlight. These photos allow the quick recognition of a chemical by its packaging. Because the QR code labels are also imprinted with text identifying commercially available chemicals, the tests and reagents created in the laboratory can also be described quickly and unambiguously.

Implementation of the System

To implement the new inventory system, a team of six employees took inventory of the entire stock of chemicals in barely two weeks, uploaded existing Excel files into the new system and printed labels for the chemicals and their storage locations. For each chemical the following data is now routinely registered: Name of the substance, CAS registry number, storage location, photo of the packaging, available amount, and manufacturer.

Because of the significant shortening of time searching for chemicals in daily laboratory work (2-5 minutes instead of 1-2 hours, and sometimes without success), the initial investment of time was amortized in about six months. New employees now can find the chemicals they need without having to bother others with questions. During the annual inventory the bulk-scan function has shown itself to be especially useful for updating the storage locations of chemicals. Financial savings have also been realized by Professor Rieger’s work group because significantly fewer chemicals are reordered unnecessarily.

On walking through the laboratory, Dr. Carsten Troll opened the chemical lockers and happily summed it up: “Just one year ago this would have been unthinkable. Now our chemical database is always updated, and should something ever be amiss, then we simply scan a few shelves with chemicals and update their locations. It’s that simple.”